As global industries such as oil & gas, power generation, petrochemical, and marine engineering continue to demand higher equipment reliability, valve maintenance has become a critical focus. Portable valve grinding machines are increasingly adopted for on-site valve repair, helping operators reduce downtime, labor costs, and logistical challenges. This guide provides a practical overview to help maintenance teams and procurement managers choose the right portable valve grinding machine for their applications.

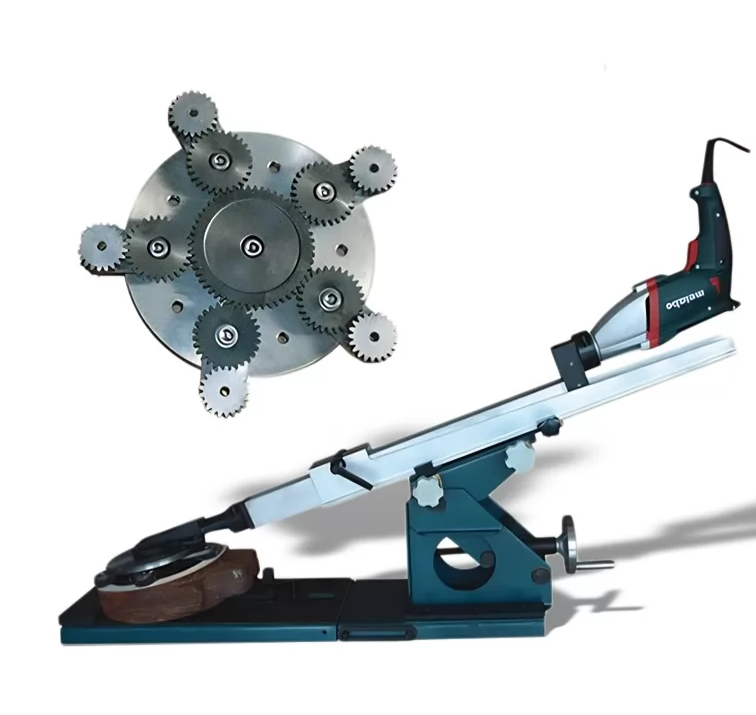

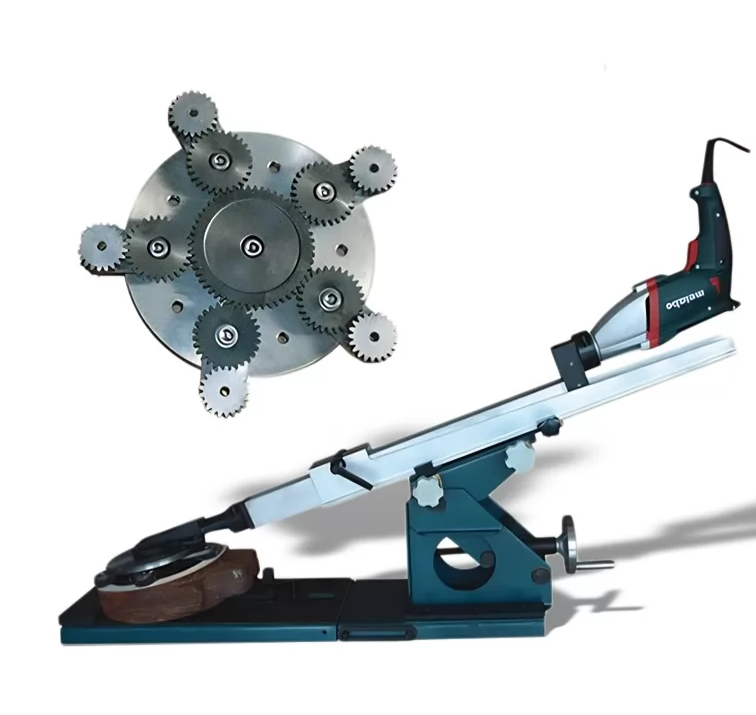

What Is a Portable Valve Grinding Machine?

A portable valve grinding machine is a compact, mobile solution designed for in-situ valve seat grinding, lapping, and resurfacing. Unlike traditional workshop-based machines, portable units can be transported directly to the job site, allowing technicians to perform valve maintenance without removing valves from pipelines or systems. This capability is especially valuable in remote locations and critical production environments where downtime must be minimized.

Key Industries Using Portable Valve Grinding Machines

Portable valve grinding machines are widely used across multiple heavy industries. In the oil and gas sector, they support maintenance of gate valves, globe valves, and safety valves during shutdowns and turnarounds. Power plants rely on them to service high-pressure steam valves, while chemical and petrochemical facilities use them to maintain corrosion-resistant alloy valves. Marine and offshore platforms also benefit from portable solutions due to limited workspace and difficult access conditions.

Valve Types and Size Compatibility

When selecting a portable valve grinding machine, the first consideration should be valve type and size range. Different machines are designed to handle specific valve geometries, including flat-seat, conical-seat, and spherical valves. Ensure the machine supports the minimum and maximum valve diameters required for your operation. For facilities with diverse valve inventories, choosing a model with interchangeable tooling and wide size coverage can significantly improve flexibility.

Grinding Accuracy and Surface Finish

Precision is critical in valve maintenance, as improper grinding can lead to leakage, pressure loss, or premature failure. High-quality portable valve grinding machines offer precise alignment systems, stable spindle performance, and adjustable feed control. When evaluating equipment, consider achievable surface roughness, concentricity, and repeatability. These factors directly affect valve sealing performance and operational safety.

Portability and On-Site Usability

True portability goes beyond compact size. Weight, modular design, and ease of assembly all impact on-site usability. Machines designed for field service should be easy to transport, quick to set up, and operable in confined or elevated spaces. Features such as lightweight frames, quick-lock components, and intuitive controls can significantly reduce setup time and operator fatigue during extended maintenance tasks.

Power Source and Operating Environment

Portable valve grinding machines are available with electric, pneumatic, or hydraulic drive systems. Electric models are common for plant environments with stable power supply, while pneumatic versions are preferred in hazardous or explosive zones. Hydraulic systems offer high torque for large-diameter or hard-material valves. Always match the power option to your site conditions, safety requirements, and available utilities.

Maintenance, Durability, and After-Sales Support

Durability is essential for equipment operating in harsh industrial environments. Look for machines constructed from robust materials with proven resistance to vibration, heat, and corrosion. In addition, reliable after-sales support, spare parts availability, and technical training are key factors often overlooked during purchasing decisions. A well-supported machine delivers long-term value and ensures consistent maintenance quality.

Conclusion: Choosing the Right Solution

Selecting the right portable valve grinding machine requires balancing precision, portability, compatibility, and long-term support. By carefully evaluating valve types, operating conditions, and maintenance goals, operators can invest in a solution that improves efficiency and extends valve service life. As industries continue to prioritize uptime and cost control, portable valve grinding machines remain a smart and strategic maintenance investment.