The valve grinding machine is a commonly used method of finishing the sealing surface in the valve manufacturing process. Grinding can make the valve sealing surface obtain high dimensional accuracy, geometric shape accuracy, and surface roughness, but it cannot achieve the mutual position accuracy between the surfaces of the sealing surface. In the grinding process, the grinding tool and the surface of the sealing ring are well bonded together, and the grinding tool makes complex grinding movements along the bonding surface. An abrasive is placed between the surface of the grinding tool and the sealing ring. When the grinding tool and the surface of the sealing ring move relative to each other, part of the abrasive particles in the abrasive slide or roll between the surface of the grinding tool and the sealing ring, and the surface of the sealing ring is very thin. A layer of metal. The convex peaks on the upper surface of the sealing ring are firstly ground off, and then gradually reach the required geometric shape.

Grinding is not only the mechanical processing of metals by abrasives but also chemical effects. The grease in the abrasive can form an oxide film on the processed surface, thereby accelerating the grinding process.

The basic principle of sealing surface grinding

The basic principle of sealing surface grinding includes five aspects: grinding process, grinding movement, grinding speed, grinding pressure and grinding allowance.

1. Grinding process

The grinding tool and the surface of the sealing ring are well bonded together, and the grinding tool makes complex grinding movements along the bonding surface. An abrasive is placed between the surface of the grinding tool and the sealing ring. When the grinding tool and the surface of the sealing ring move relative to each other, part of the abrasive particles in the abrasive slide or roll between the surface of the grinding tool and the sealing ring, and the surface of the sealing ring is very thin. Layer of metal. The convex peaks on the upper surface of the sealing ring are firstly ground off, and then gradually reach the required geometric shape.

Grinding is not only the mechanical processing of metals by abrasives, but also chemical effects. The grease in the abrasive can form an oxide film on the processed surface, thereby accelerating the grinding process.

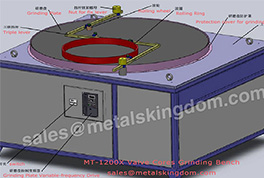

Valve Grinding Machine

2. Grinding exercise

When the lap and the surface of the sealing ring move relative to each other, the relative sliding distance of each point on the surface of the sealing ring to the lap should be the same. And, the direction of relative movement should be constantly changed. The continuous change of the direction of movement prevents each abrasive particle from repeating its own motion track on the surface of the seal ring, so as to avoid obvious scratches and increase the surface roughness of the seal ring. In addition, the continuous change of the movement direction can also make the abrasive distribution more uniform, so that the metal on the surface of the seal ring can be cut more uniformly.

Although the grinding movement is complicated and the direction of movement is changing, the grinding movement is always carried out along the surface of the grinding tool and the surface of the sealing ring. Whether it is manual grinding or mechanical grinding, the geometric accuracy of the sealing ring surface is mainly affected by the geometric accuracy of the research tool and the grinding movement.

3. Grinding speed

The faster the grinding speed, the higher the grinding efficiency. The grinding speed is fast, and more abrasive particles pass on the surface of the workpiece in a unit time, and more metal is cut off.

4. Grinding pressure

The grinding efficiency increases as the grinding pressure increases.

When grinding the sealing surfaces of cast iron, copper, and austenitic stainless steel materials, the grinding pressure is 0.1MPa~0.3MPa; the sealing surfaces of hardened steel and cemented carbide are 0.15MPa~0.4MPa. The larger value is used for rough grinding, and the smaller value is used for fine grinding.

5. Grinding allowance

Due to the grinding stone finishing process, the cutting volume is small. The size of the grinding allowance depends on the processing accuracy and surface roughness of the previous process. Under the premise of ensuring the removal of the processing traces of the previous process and the correction of the geometric error of the seal ring, the smaller the grinding allowance, the better. The sealing surface is generally finely ground before grinding. The sealing surface after fine grinding can be directly finely ground.

We are the valve grinder supplier, if you are interested in our products, please feel free to contact us.