YM-120 Milling Type Plate Beveling Machine

1.Suitable for processing work piece materials with high rigidity, hardness, and heat resistance;

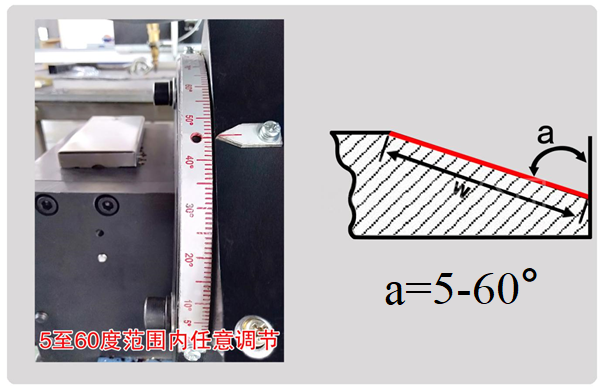

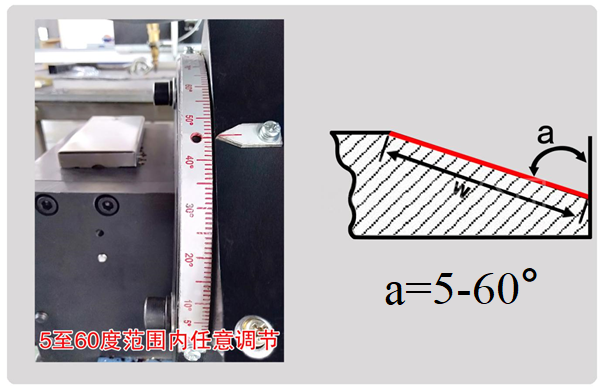

2.The angle range of the bevel can be adjusted freely within the range of 5° to 60°;

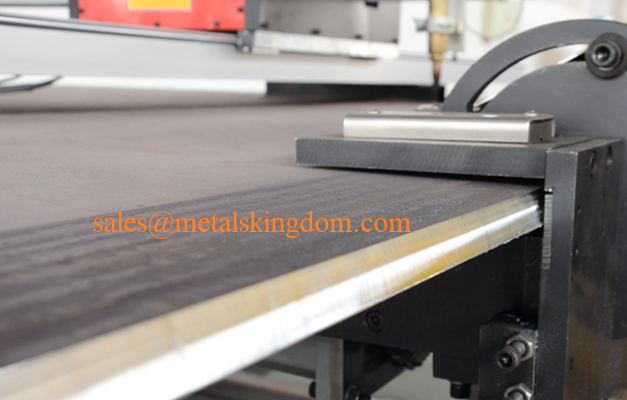

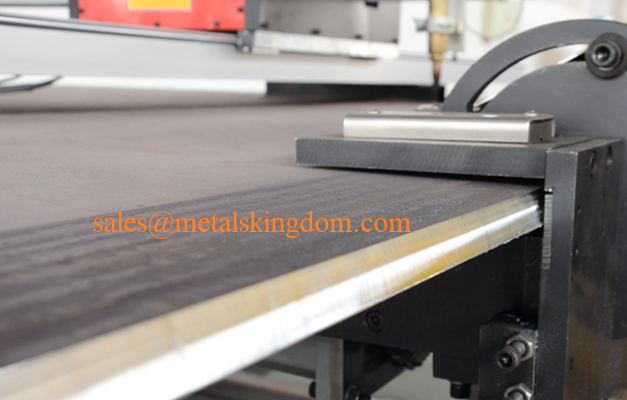

3.Rear mounted Reducer is beneficial for processing narrow plates and is more stable and safe;

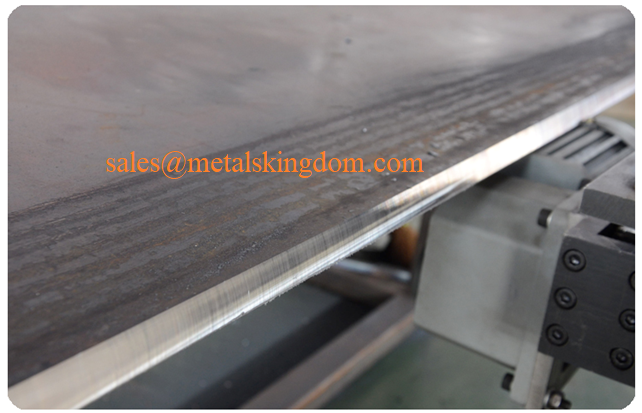

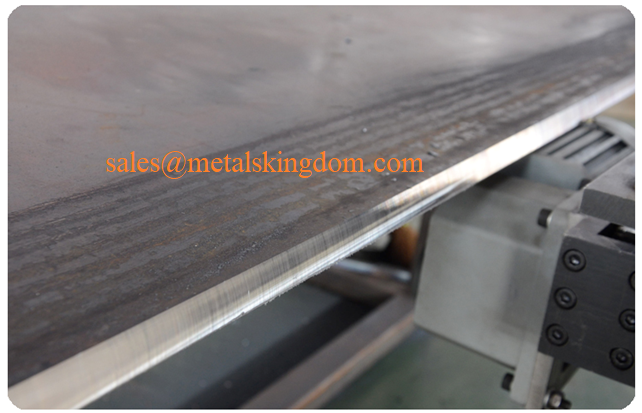

4.The surface smoothness of the processed bevel reaches Ra3.2-6.3, fully meeting the welding requirements of pressure vessels;

5.Small in size and light in weight, it is a portable automatic walking milling machine and also a moving and portable beveling machine;

6.Cold cutting bevel processing does not change the hardness of the material, and there is no oxide layer on the bevel surface;

High-Speed Plate Beveling Machine

The High-Speed Plate Beveling Machine is an automatic milling type solution designed for precise edge preparation of steel plates. As a professional plate beveling machine supplier, Metals Kingdom provides high-efficiency, stable, and customizable beveling equipment for heavy-duty industrial applications worldwide.

This series of beveling machines is used for pre welding metal plate beveling. It mainly utilizes the milling principle to mill and cut the edges of the steel plate at the desired angle to obtain the required beveling for welding. It solves the disadvantages of high manual intensity, non-standard angles, rough slopes, and high working noise in flame cutting, polishing machine grinding processes, significantly reducing oxygen and acetylene gas energy consumption and labor costs. More effectively avoiding the disadvantages of deformation and hardness degeneration of the board after flame cutting.

This machine can automatically walk according to the edge of the material, with convenient angle adjustment, easy operation, high efficiency, environmental protection, precise angle, smooth surface, and particularly outstanding characteristics for stainless steel processing.

Mainly used for ordinary structural steel, cast iron, hard plastics, stainless steel, non-ferrous metals and other materials in shipbuilding, metallurgy, pressure vessels, steel structures, petrochemicals, power, heavy industry, mechanical processing plants, mining and aerospace welding fields.

Specializing in stainless steel (pressure vessel) bevels.

Plate Beveling Machine for Automatic Steel Plate Edge Preparation

This automatic plate beveling machine is designed to process steel plate edges with high precision and repeatability. Compared with traditional cutting or grinding methods, milling type beveling ensures smoother bevel surfaces and consistent bevel angles, improving welding quality and efficiency.

Automatic feeding and beveling operation

High precision edge preparation

Stable performance for continuous production

Ideal for medium to heavy steel plates

Plate Edge Beveling Machine with Milling Head

Equipped with a high-performance milling head, this plate edge beveling machine delivers clean and accurate bevels for welding preparation. The milling head design allows fast material removal while maintaining excellent surface finish.

Milling type plate beveling machine

Replaceable carbide inserts

Uniform bevel angle and width

Low vibration and high cutting efficiency

Milling Beveling Machine for Steel Plates

This milling beveling machine for steel plates is suitable for carbon steel, stainless steel, and alloy steel. It supports various bevel shapes, making it a versatile solution for different welding standards.

V, Y, X, and K bevel profiles

Adjustable bevel angle

Consistent bevel quality for welding joints

Designed for industrial steel fabrication

High-Speed Plate Beveling Machines for Industrial Production

As a high-speed plate beveling machine, this equipment significantly improves productivity in steel processing lines. The automatic operation reduces labor cost and ensures stable output in batch production.

High-speed milling beveling process

Automatic travel along plate edge

Reduced processing time per plate

Suitable for production workshops

Steel Plate Beveling Machine for Heavy-Duty Applications

This steel plate beveling machine is widely used in heavy industries requiring reliable and repeatable edge preparation.

Shipbuilding and offshore fabrication

Pressure vessel manufacturing

Steel structure and bridge construction

Pipeline and heavy equipment fabrication

Technical Parameters of Plate Beveling Machine

Machine type: Automatic plate beveling machine

Beveling method: Milling type

Applicable materials: stainless steel

Bevel angle: Adjustable according to requirement

Operation mode: Automatic

OEM & Custom Plate Beveling Machine Manufacturer

Metals Kingdom is an experienced plate beveling machine manufacturer, offering OEM and custom solutions to meet different production needs.

OEM & ODM plate beveling machine service

Customized bevel angle and plate thickness range

Custom machine size and configuration

Private label and branding support

Plate Beveling Machine Price & Wholesale Supply

The plate beveling machine price depends on configuration, automation level, and customization requirements. Metals Kingdom provides competitive factory pricing and stable supply for global distributors and industrial buyers.

Factory direct pricing

Wholesale and bulk order support

Cost-effective solution for long-term use

Fast production and delivery

Why Choose Metals Kingdom as Your Plate Beveling Machine Supplier?

As a reliable plate beveling machine supplier, Metals Kingdom focuses on product quality, technical expertise, and long-term cooperation with B2B customers.

Professional beveling machine manufacturer

Strict quality control and testing

Rich experience in steel processing equipment

Responsive technical and after-sales support

Contact Metals Kingdom for Plate Beveling Machine Solutions

If you are looking for a reliable plate beveling machine manufacturer or need an automatic milling type plate beveling machine, contact Metals Kingdom today. Our technical team is ready to provide professional solutions for your steel fabrication and welding preparation projects.

Product Features

2.1 Suitable for processing work piece materials with high rigidity, hardness, and heat resistance;

2.2 The angle range of the bevel can be adjusted freely within the range of 5° to 60°;

2.3 Rear mounted Reducer is beneficial for processing narrow plates and is more stable and safe;

2.4 The surface smoothness of the processed bevel reaches Ra3.2-6.3, fully meeting the welding requirements of pressure vessels;

2.5 Small in size and light in weight, it is a portable automatic walking milling machine and also a moving and portable beveling machine;

2.6 Cold cutting bevel processing does not change the hardness of the material, and there is no oxide layer on the bevel surface;

3. Selection Parameters

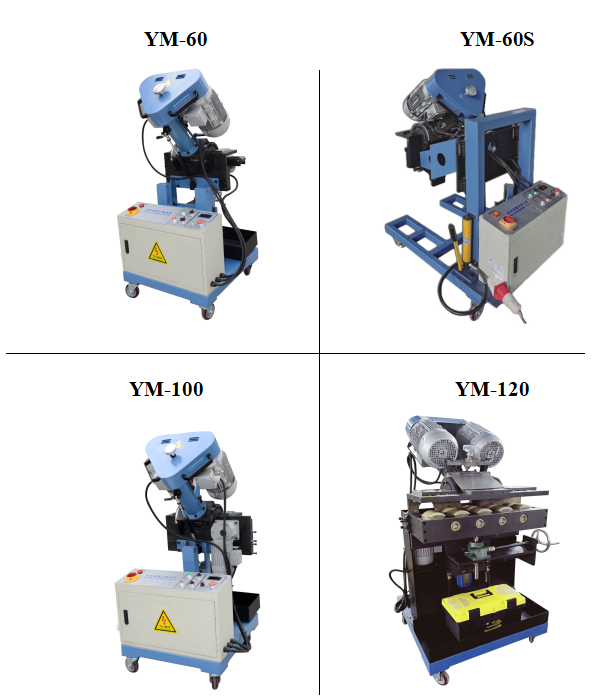

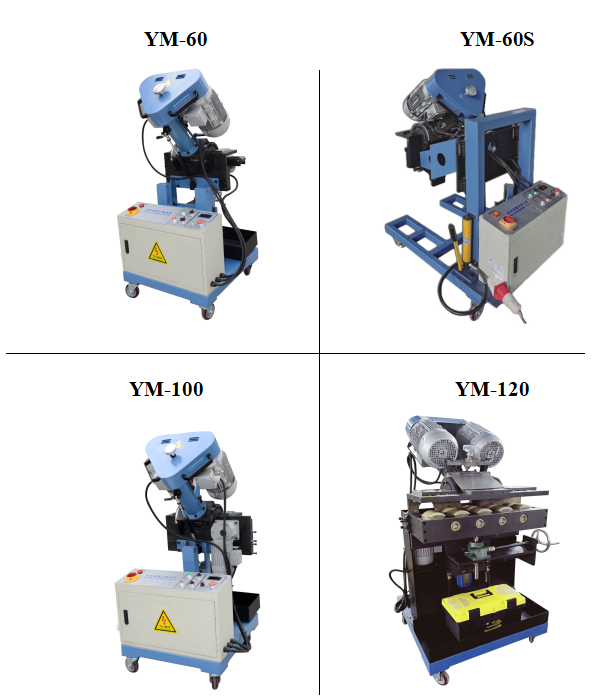

Parameters / Model | YM-60 | YM-60S | YM-100 | YM-120 |

Power supply | AC380V 50HZ | AC380V 50HZ | AC380V 50HZ | AC380V 50HZ |

Total power | 4.8kw | 4.8kw | 6.4kw | 6.4kw |

Main motor power | 2.2kw×2 | 2.2kw×2 | 3.0kw×2 | 3.0kw×2 |

Power of walking motor | 400w | 400w | 400w | 400w |

Feed Speed | 0-1.5m/min | 0-1.5m/min | 0-1.5m/min | 0-1.5m/min |

Cutter head speed | 1100r/min | 1100r/min | 1100r/min | 1100r/min |

Clamping thickness | 6-50mm | 6-50mm | 6-60mm | 8-100mm |

Clamping width | >80mm | >80mm | >80mm | >100mm |

Once bevel width | 0-20mm | 0-20mm | 0-20mm | 0-30mm |

Bevel width | 0-40mm | 0-40mm | 0-50mm | 0-50mm |

Number of blades | 6 pieces | 6 pieces | 6 pieces | 6 pieces |

Bevel type | V, Y | V, Y | V, Y | V, Y, U, J |

Bevel angle | 0°~60° | 0°~60° | 0°~60° | 0°~90° |

Processing material | Stainless steel, carbon steel, alloys, etc | Stainless steel, carbon steel, alloys, etc | Stainless steel, carbon steel | Stainless steel, carbon steel |

4. Series Products