After long-term use of the valve, the valve flap and seat sealing surface will be worn, the tightness is reduced. Repairing the sealing surface is a large and very important task. The main method of repair is grinding. The sealing surface of serious wear is first welded by turning to process and then grinding.

Grinding of valves includes:

● Cleaning and inspection process.

● Grinding process.

● Inspection process.

Cleaning and inspection process

Cleaning the sealing surface in the oil pan, using a professional cleaning agent, while washing to check the damage of the sealing surface. Fine cracks that are difficult to determine with the naked eye can be carried out by the coloring detection method.

After cleaning, the valve flap or gate valve should be checked with the sealing surface of the valve seat tightness, check with red and pencil. Use red Dan test red, check the seal surface seal shadow, to determine the seal surface fit; or pencil in the valve and seat sealing surface on a few concentric circles, and then the valve and seat close rotation, check the pencil circle erases situation, to determine the seal surface fit.

If the fit is not good, the standard plate can be used to test the valve or gate sealing surface and valve body sealing surface, respectively, to determine the grinding parts.

Grinding process

The grinding process is essentially a cutting process without a lathe, valve head, or seat pockmark or small hole depth is generally within 0.5mm, you can use the method of grinding for maintenance. The grinding process is divided into coarse grinding, medium grinding, and fine grinding.

Rough grinding is to eliminate the sealing surface of the abrasion, indentation, corrosion points, and other defects, so that the sealing surface gets a high degree of flatness and a certain degree of finish, to lay the foundation for the sealing surface of the medium grinding.

Rough grinding using grinding head or grinding seat tools, using coarse sandpaper or coarse grinding paste, its particle size 80#-280#, coarse particle size, cutting volume, high efficiency, but the cutting pattern is deeper, the sealing surface is rougher. Therefore, coarse grinding is enough to remove the pockmarks on the valve head or valve seat as long as they are flat.

Medium grinding is to eliminate the coarse grain on the sealing surface and further improve the flatness and finish of the sealing surface. The use of fine-grained sandpaper or fine-grained grinding paste, the particle size of 280 # - W5, fine particle size, small cutting volume, which is conducive to reducing the roughness; at the same time should be replaced with the corresponding research tools, research tools should be clean and clean.

After the middle grinding, the contact plane of the valve should reach brightness. If you use a pencil on the valve head or seat a few lines, the valve head or seat against a light turn, the pencil

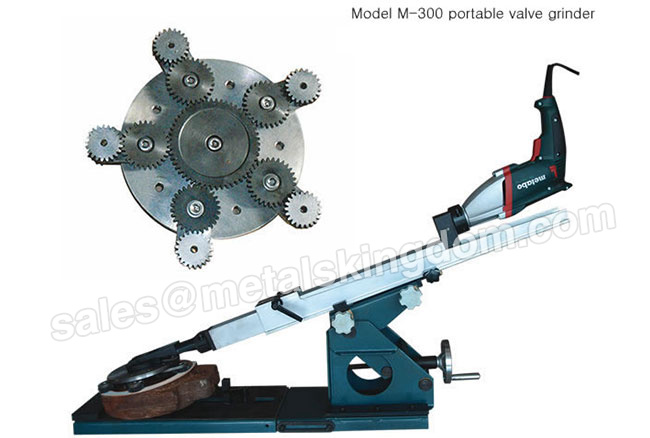

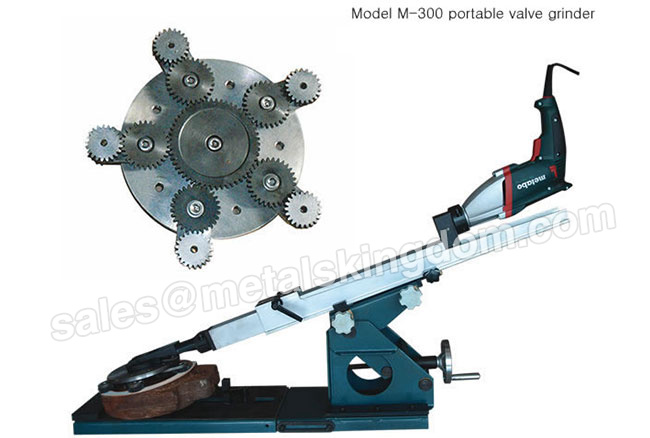

We are a valve grinding machines supplier, please feel free to contact us if you need them.