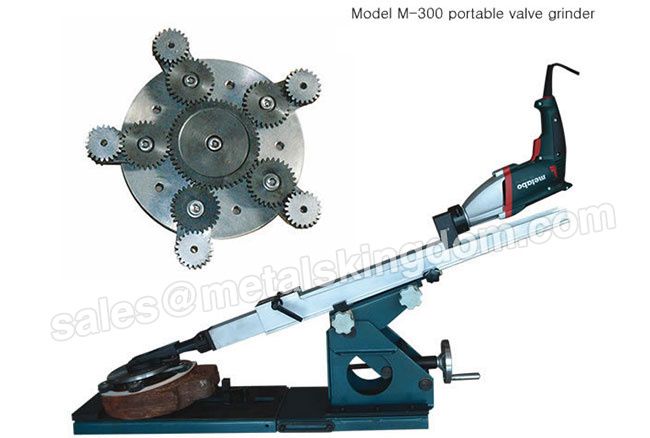

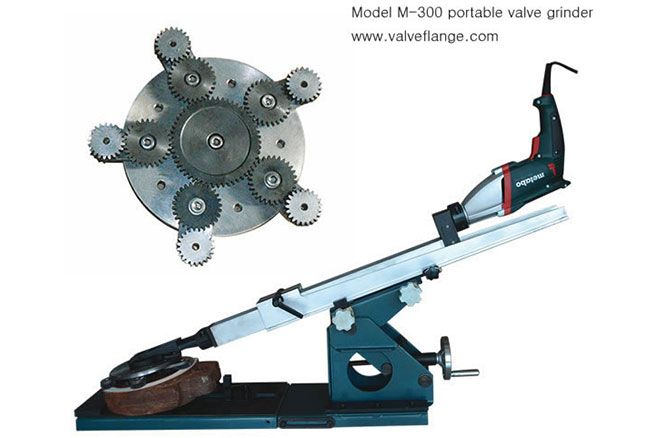

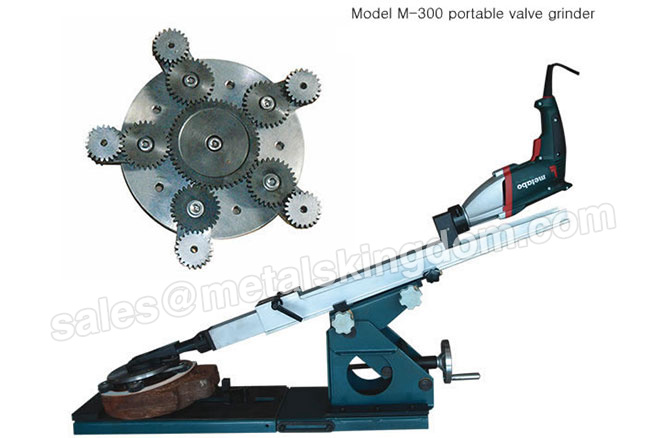

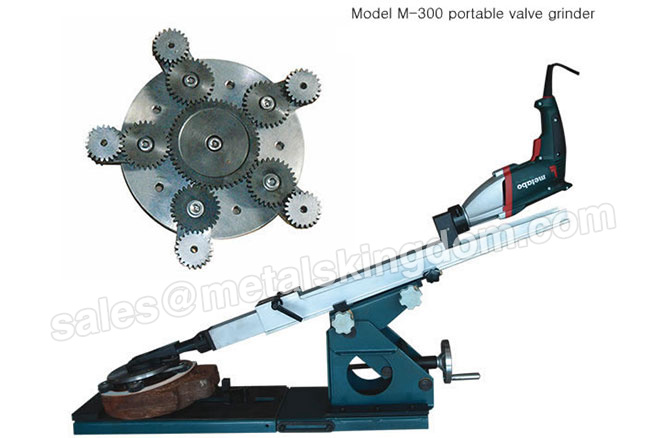

M300 DN95-320mm (4-13Inch) Portable Gate Valve Grinding Machine

Technical Parameter of Gate Valve Lapping Machine

1) Applicstion:Gate Valve Seat,Gate Valve Core.

2) Grinding scope: DN95-320mm (4"-13")

3) Motor power: 1100W

4) Rated Voltages: 220V

5) Min distance of valve seal face: B>55mm

6) Allowed adjustable length: L≤650mm

7) Operating weight: 20kg

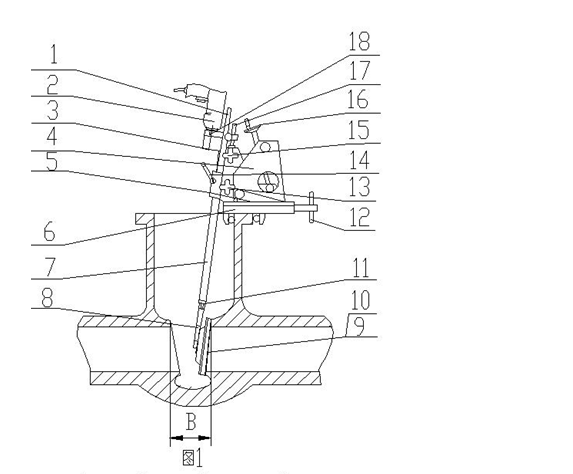

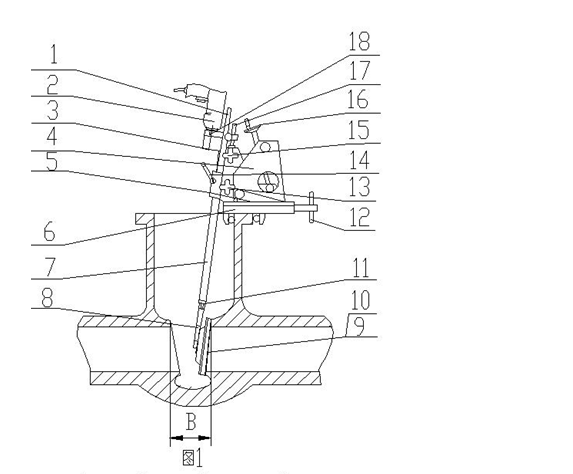

Structure of Gate Valve Lapping Machine

1.Main body 2.electric motor 3.power box 4.adjusting bracket 5.screw bolt 6.base 7.telescopic boom

8.arm 9grinding disc 10screw bolt 11screw bolt 12 clamping rod 13Fastening handle 14.telescopic boom lock arm 15.left or right adjusting handwheel 16.handwheel 17.sliding crame 18.screw bolt

Overview of Gate Valve Lapping Machine

Model M-300 Gate Valve Lapping Machine is widely used in the industries such power generation, petroleum, chemical, metallurgy and paper making as a high-tech product with national patent. It has the following characteristics:

1) Light, compact, and easy to carry

2) Split-type assembly makes installation easy and fast

3) Available in various field work

4) Applicable in grinding gate, check valves and flanges made of various materials

5) Grinding automatically after the installation is adjusted well

6) Reasonable structure design, perfect Metabo motor and high-quality imported grinding materials contribute to the grinding 3-10 times as fast as the manual one

7) Stepless and adjustable speed, stable power transmission and accurate lapping make the sealing face in complete contact.

If you need other types of portable valve grinders, you can click here.

Technical Parameter of Gate Valve Lapping Machine

1) Applicstion:Gate Valve Seat,Gate Valve Core.

2) Grinding scope:DN95-320mm 4"-13"

3) Motor power: 1100W

4) Rated Voltages: 220V

5) Min distance of valve seal face: B>55mm

6) Allowed adjustable length: L≤650mm

7) Operating weight: 20kg

If you have any questions or needs, you are welcome to consult us at any time!

Note when using the Gate Valve Lapping Machine:

1. Turn on the 220V single-phase AC power supply. The power socket should match the power plug of the motor belt.

2. Familiar with the use of Gate Valve Lapping Machine. The operating instructions for the motor should be read carefully. A brief description is as follows: The speed of the Gate Valve Lapping Machine is controlled by changing the switch pressure. The Gate Valve Lapping Machine revs low when the switch is flicked and increases as the pressure increases.

3. The forward and reverse can be changed by the forward and reverse switch. In addition, the motor speed can also be adjusted through the rotary switch. The rotary switch is in the neutral position when it is perpendicular to the motor shaft. The switch is equipped with a flywheel. When the small wheel rotates clockwise in the direction of the flywheel arrow, the speed increases. When you turn the speed control wheel counterclockwise, the speed will decrease.

4. When using the Gate Valve Lapping Machine, generally adjust the speed control wheel to the lowest point, then turn on the motor, and then press the control button (ie the lock button, the black button behind the motor handle), the Gate Valve Lapping Machine is in the state of autorotation , and then the speed is very small.

5. Wheels adjust the speed to the desired desired speed. When shutting down, adjust the speed to the low point first, then press the switch, the locking button can be automatically released, and the switch can be released. machine.

6. Before grinding, be sure to check whether there are high points on the damaged surface of the valve surface. If there is a high point, it should be trimmed first to avoid impacting the grinding disc or changing the angle of the surface to be polished.

7. After use, clean the grinding disc or the dirt on the grinding disc. Use scissors to cut the double-sided tape sandpaper (cloth) according to the diameter of the sandpaper, and stick it on the cleaned grinding seat (disc).

8. If the temperature of the repaired valve is high or there is water, a random diamond grinding disc can be used to fix the grinding disc on the grinding disc for grinding. Water or kerosene should be appropriately added during the grinding process to facilitate grinding and rinsing.

9. Be sure to unplug the motor after use to avoid accidentally bumping the motor switch. Abrasive discs can injure or damage the machine. IMPORTANT: Unplug the motor power plug after shutdown.

10. Apply a small amount of butter to the gears when using.

Don't hesitate to choose us to get the best quality products and the best prices!